Meeting the Demands of Modern Logistics with Industrial-Grade Warehouse Flooring

News

Warehouse flooring is a fundamental yet often underestimated part of modern logistics infrastructure. As fulfilment...

Read More

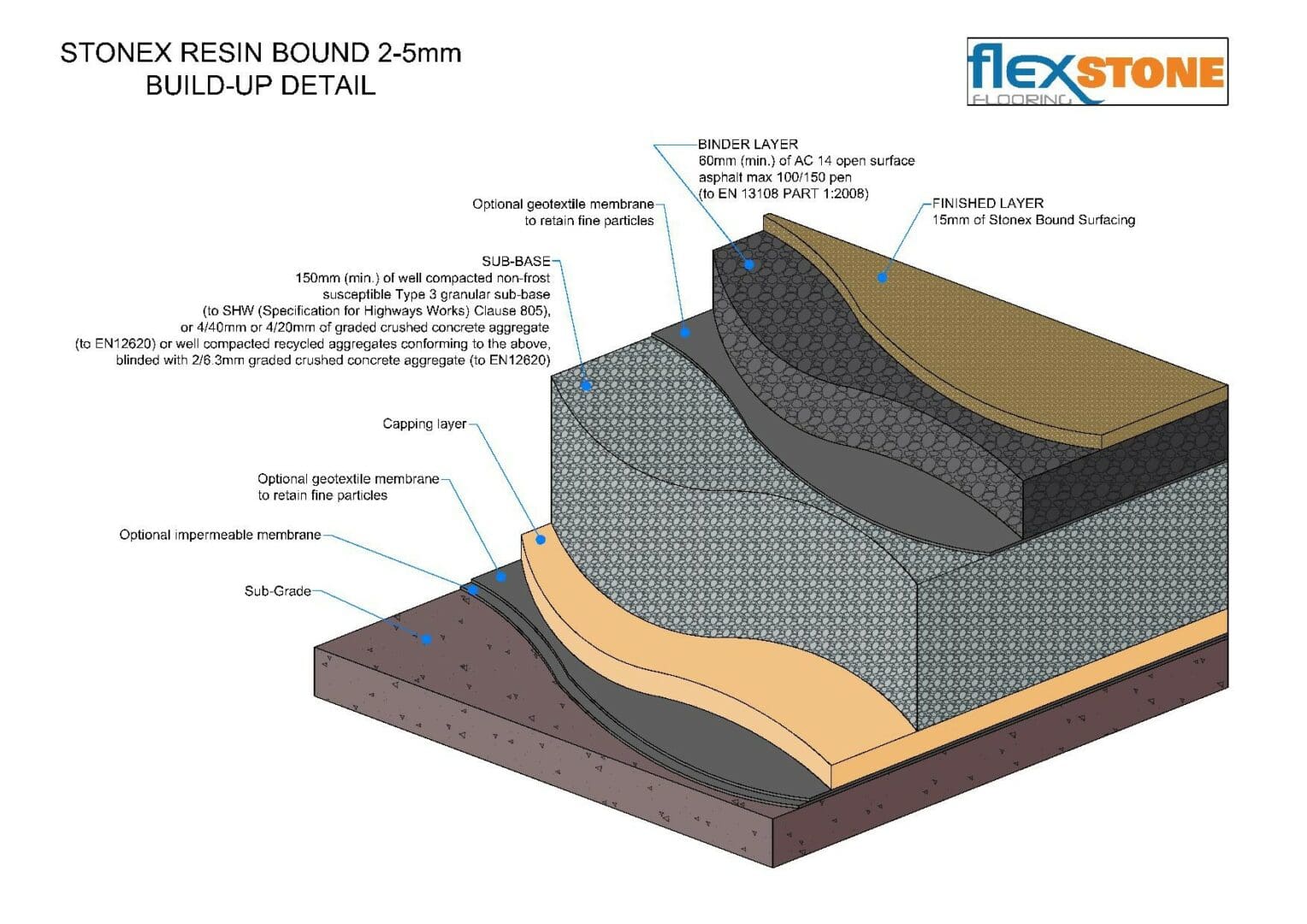

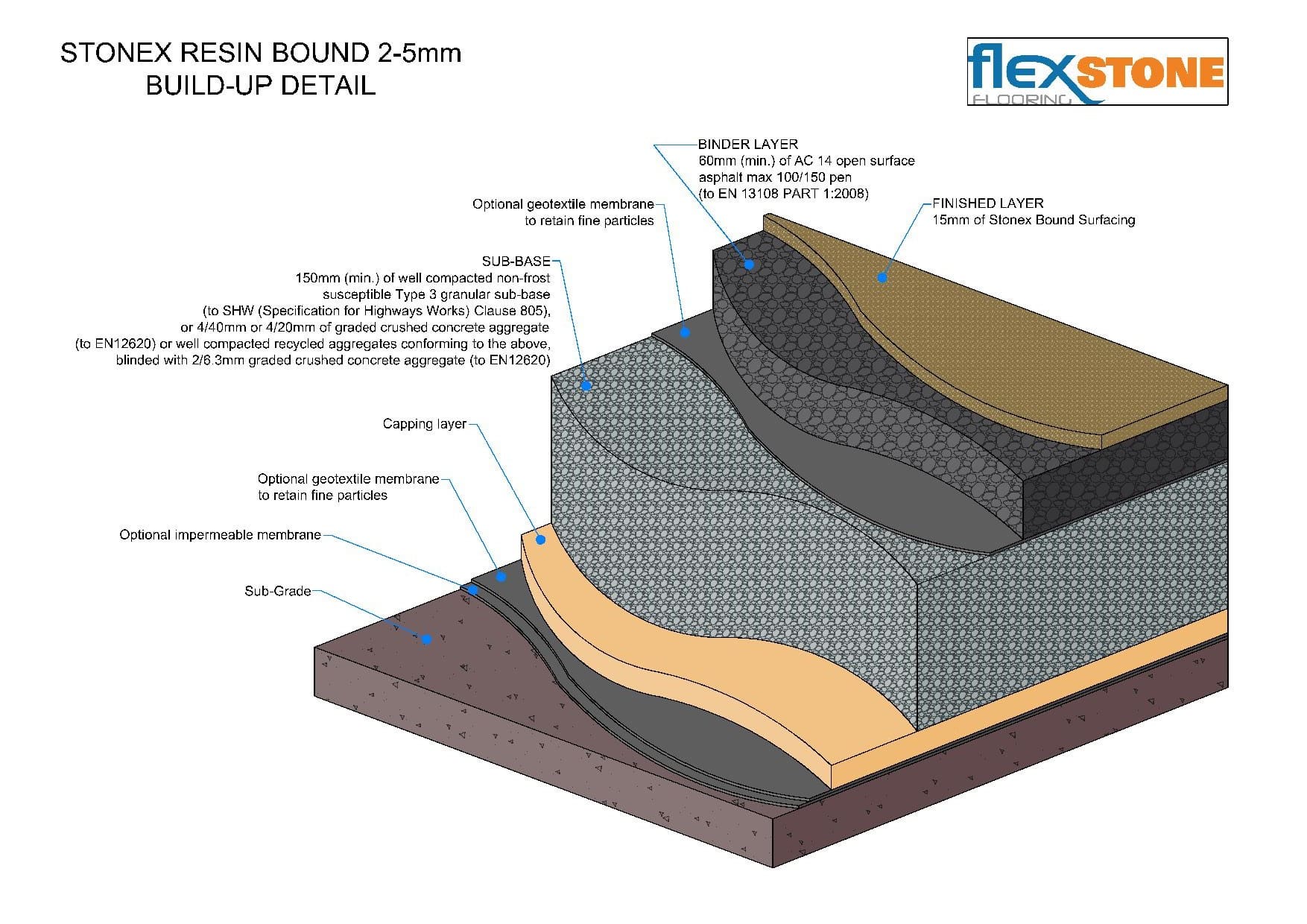

Resin driveways applied to the correct thickness provide a highly durable and incredibly low-maintenance finish, which looks fantastic. Whether you’re after a uniform, block-coloured resin driveway or a contemporary pattern, the thickness of your resin driveway is all important.

If you’re considering a resin driveway, this guide will identify some of the crucial elements that ensure your drive is fit for vehicle usage and avoids the common issues where resin bound systems are applied too quickly or through poor application methods.

[quote_block heading=”Looking for resin driveway quotes?” text=”Fill out our contact form with more details about your driveway and we’ll get in touch with a more accurate, no-obligation resin driveway cost.” link=”https://flexflooring.co.uk/contact/”]

No matter the size or curves of your drive, the surface application depth is essential to guarantee your sleek resin driveway performs to your expectations.

As an absolute minimum:

If you’re unsure of the appropriate depth for a resin driveway, the easy solution is to look at the aggregate size and ensure your contractor has allowed for a viable depth.

If a resin driveway is not thick enough, the result is usually cracking because a resin drive is layered with different substrates rather than one solid mixture.

To take a quick look at the possible issues:

Applying sub-layers incorrectly causes stress at the surface, which usually means that the weakest points, around corners and maintenance hole covers, show the first signs of damage.

Along with the resin driveway thickness, there are several other common faults during the application process that could impact the appearance and durability of your driveway:

Professional resin driveway applications, with due care paid to each stage, avoid any mistakes that negatively affect the performance and quality of your resin driveway.

Incorrect thickness is one the most frequent resin driveway problems we encounter. Hiring an experienced contractor is the best way to ensure you have a beautiful, smooth resin driveway laid correctly and designed to last for the years to come.

Attention to details such as proper surface preparation will eliminate the risk of issues such as rippling.

Although much depends on the size of the stones and your expected usage of your drive, a resin drive should be laid to at least 16mm – any shallower, and the surface may begin to break apart.

If you would like more information about the correct resin driveway thickness for your property or to explore design inspiration, please visit the Flexflooring Resin Bound Driveway costs page, or get in touch for expert advice.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

News

Warehouse flooring is a fundamental yet often underestimated part of modern logistics infrastructure. As fulfilment...

Read More