Meeting the Demands of Modern Logistics with Industrial-Grade Warehouse Flooring

News

Warehouse flooring is a fundamental yet often underestimated part of modern logistics infrastructure. As fulfilment...

Read More

A cracked concrete floor near your main loading bay might not seem urgent until a forklift skids, a pallet tips, or a staff member falls. In a warehouse, flooring problems escalate quickly. Safety, efficiency, and even legal compliance can hinge on the surface your team walks and works on.

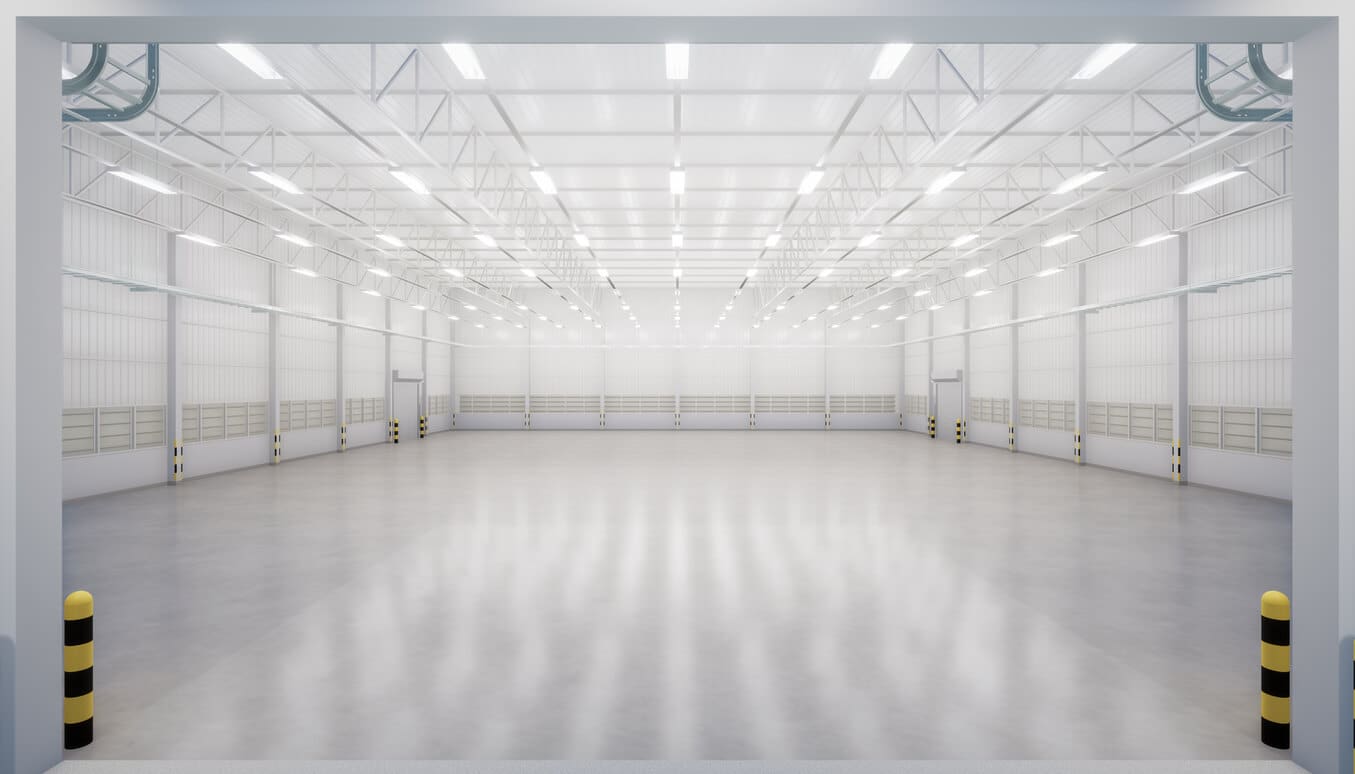

If you manage warehouse operations, you already understand how essential the right flooring is to safety and productivity. High-performance warehouse flooring reduces risk, supports productivity, and withstands the daily demands of industrial settings. It’s a key part of keeping your site running safely and efficiently.

[quote_block heading=”Looking for a free resin flooring quote?” text=”Fill out our contact form with more details about your resin project and we’ll get in touch with a more accurate, no-obligation cost.” link=”http://flexflooring.co.uk/contact/”]

Warehouse flooring supports shelving, vehicles, and the overall efficiency of your site. Every movement in a warehouse relies on a surface that’s safe, stable, and suited to the demands of the job. Poor flooring creates friction in your operations, leading to:

A failing floor affects safety, slows down operations, and disrupts daily performance. Choosing the right warehouse flooring gives you a foundation that keeps pace with your daily workload.

Some of the most frequent risks we see in underperforming warehouse flooring include:

Health and safety regulations require employers to maintain floors that are suitable for their purpose. If the floor is cracked, slick, or hard to clean, you may be exposing your team to preventable hazards.

At Flex, we recommend resin-based systems for most industrial flooring projects. Here’s why:

The right system depends on your environment. We typically use:

Our team helps you identify the most appropriate warehouse flooring system based on how your space is used and what safety challenges you’re facing.

Safety depends on both the surface itself and how your space is planned and marked. Resin floors can be colour-coded or marked to define clear pedestrian zones, loading bays, forklift lanes, and hazard areas.

This makes a difference:

Line markings can further improve visibility in low-light conditions.

An industrial biomass facility required a flooring solution that could withstand constant foot traffic, heavy equipment, and exposure to industrial materials. The existing surface had become difficult to clean and posed slip risks during day-to-day operations. Flex installed a durable resin coating system designed for high performance under pressure. After installation, the site saw:

This project shows how the right resin system can solve many of the same challenges warehouse operators face such as slip risks, cleaning issues, and wear from constant use.

Under the Health and Safety at Work Act and the Workplace (Health, Safety and Welfare) Regulations 1992, employers are obligated to maintain floors that are safe and suitable for their intended use. Neglecting this can lead to:

Implementing slip-resistant warehouse flooring is a proactive measure to ensure compliance and safeguard your workforce.

Costs vary based on factors like warehouse size, existing floor condition, and chosen materials. For resin flooring, typical costs are:

Beyond material costs, consider:

Investing in high-quality resin flooring upfront can mitigate long-term expenses related to frequent repairs, safety incidents, and operational disruptions.

We install warehouse flooring for clients across the UK, including Birmingham, Manchester, Bristol, Leeds, and surrounding industrial hubs.

Good warehouse flooring lasts for years and stays safe with minimal upkeep:

Because resin flooring is seamless and highly resistant, you won’t face the ongoing patch repairs or dust issues seen with bare concrete.

Slip-resistant warehouse flooring reduces accidents, improves flow, and supports your operations day after day. If your current surface is worn, hard to clean, or starting to fail, it’s time to act.

Flex installs industrial resin flooring across warehouses of all sizes from local stockrooms to national distribution centres. We’ll help you specify a solution that meets your safety targets and keeps your workforce protected. Reach out to us at 01622 747909 or via sales@flexflooring.co.uk to upgrade your warehouse flooring today!

[quote_block heading=”Looking for a free Epoxy quote?” text=”Fill out our contact form with more details about your project and we’ll get in touch with a more accurate, no-obligation cost.” link=”http://flexflooring.co.uk/contact/”]

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

News

Warehouse flooring is a fundamental yet often underestimated part of modern logistics infrastructure. As fulfilment...

Read More