Resin driveways applied to the correct thickness provide a highly durable and incredibly low-maintenance finish, which looks fantastic. Whether you’re after a uniform, block-coloured resin driveway or a contemporary pattern, the thickness of your resin driveway is all important.

If you’re considering a resin driveway, this guide will identify some of the crucial elements that ensure your drive is fit for vehicle usage and avoids the common issues where resin bound systems are applied too quickly or through poor application methods.

Looking for resin driveway quotes?

Fill out our contact form with more details about your driveway and we’ll get in touch with a more accurate, no-obligation resin driveway cost.

Application guidelines for resin driveway thickness

No matter the size or curves of your drive, the surface application depth is essential to guarantee your sleek resin driveway performs to your expectations.

As an absolute minimum:

- Any resin driveway must be at least three times the largest aggregate size used in your driveway. For example, if you have an aggregate of 3mm to 6mm, the depth should be 18mm or more.

- Resin volume and application depth are key cost drivers – but a shallow resin drive may deteriorate quickly, and you should never sacrifice quality for cost if you want a driveway to stand the test of time.

- Shallow resin driveways will quickly break up, requiring substantial cost to remove the impaired resin and replace it. It is strongly advisable you lay a sufficient resin depth to give your drive the stability and solidity vital to long-term use.

If you’re unsure of the appropriate depth for a resin driveway, the easy solution is to look at the aggregate size and ensure your contractor has allowed for a viable depth.

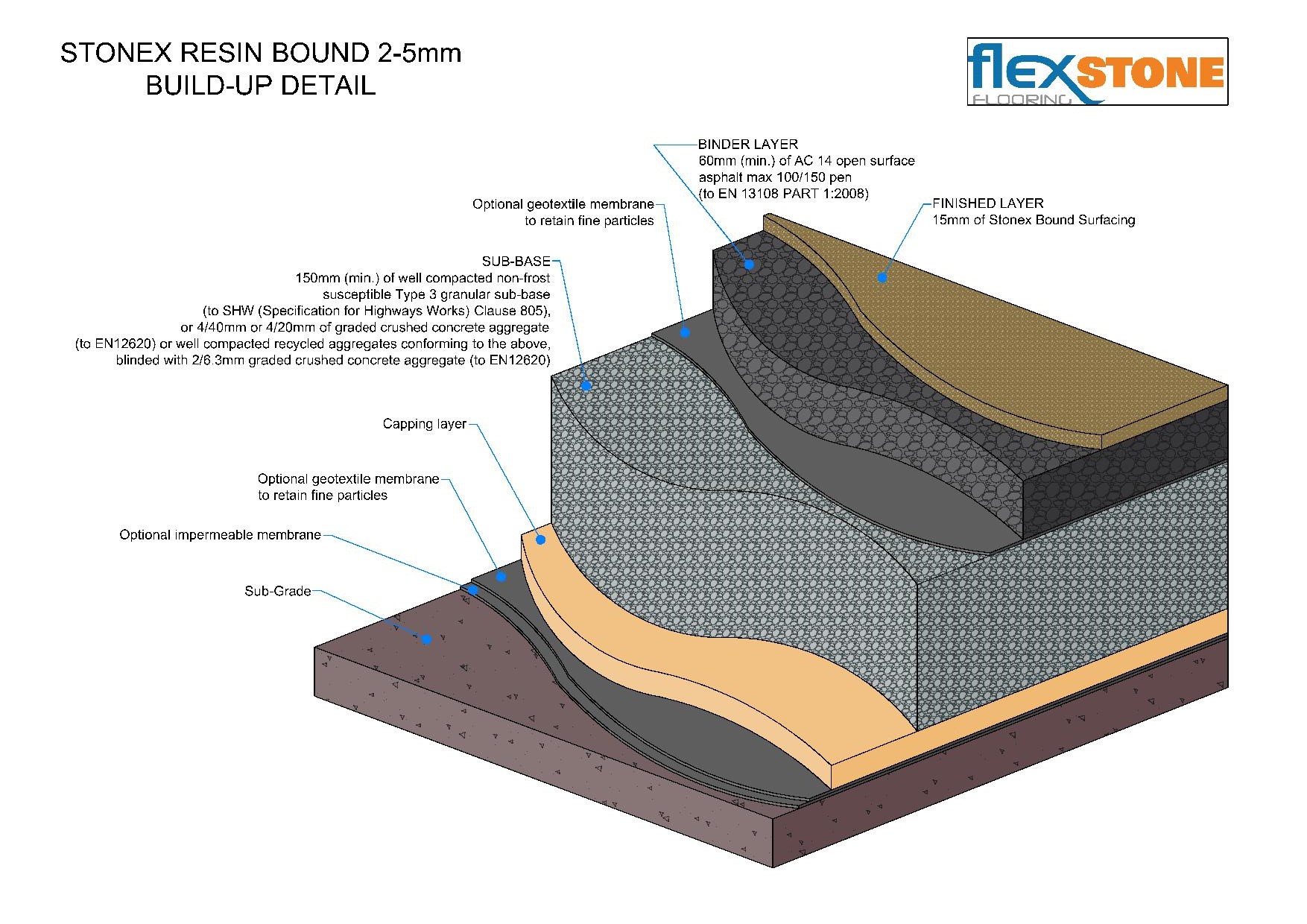

Understanding sub-driveway layers in a resin drive

If a resin driveway is not thick enough, the result is usually cracking because a resin drive is layered with different substrates rather than one solid mixture.

To take a quick look at the possible issues:

- Base movement can mean that the concrete slabs underpinning your substrate can shift if the tensile strength of the surface is exceeded – usually due to asphalt heating up in warmer weather.

- Subbase settlement occurs if the compaction ratings are too low, causing cracks to run along the surface of your resin driveway.

- Edgings are perhaps most susceptible to cracking because any timber or concrete edging can move if the adhesion strength isn’t sufficient – isolation joints along the borders can prevent this damage from occurring, along with closed-cell polyethylene strips.

Applying sub-layers incorrectly causes stress at the surface, which usually means that the weakest points, around corners and maintenance hole covers, show the first signs of damage.

Typical causes of poor quality resin driveways

Along with the resin driveway thickness, there are several other common faults during the application process that could impact the appearance and durability of your driveway:

- Incorrect ratios of resin to aggregate: bound surface resin is a high-value product, but cutting corners and costs by using less resin in the mixture will cause a soft, spongy surface that begins to break away. Resin should be concentrated to at least 6% to 8%.

- Resin driveway surfaces should be primed with a precise amount of primer. If the layer is too thick, the reaction with the moisture means the resin can’t adhere properly. Likewise, any surface damage during the curing process can cause imprints.

- Contractors must avoid dampness during each part of the process – any rain or moisture that reaches the resin can weaken the layers and impact the finish.

- Excessive heat may cause resin driveways to cure too fast, sometimes in as little as ten minutes on the hottest summer days. Laying resin early in the morning or outside of the warmest parts of the day can help, along with regular surface temperature testing.

Professional resin driveway applications, with due care paid to each stage, avoid any mistakes that negatively affect the performance and quality of your resin driveway.

Avoiding problems with resin driveway thickness

Incorrect thickness is one the most frequent resin driveway problems we encounter. Hiring an experienced contractor is the best way to ensure you have a beautiful, smooth resin driveway laid correctly and designed to last for the years to come.

Attention to details such as proper surface preparation will eliminate the risk of issues such as rippling.

Although much depends on the size of the stones and your expected usage of your drive, a resin drive should be laid to at least 16mm – any shallower, and the surface may begin to break apart.

If you would like more information about the correct resin driveway thickness for your property or to explore design inspiration, please visit the Flexflooring Resin Bound Driveway costs page, or get in touch for expert advice.